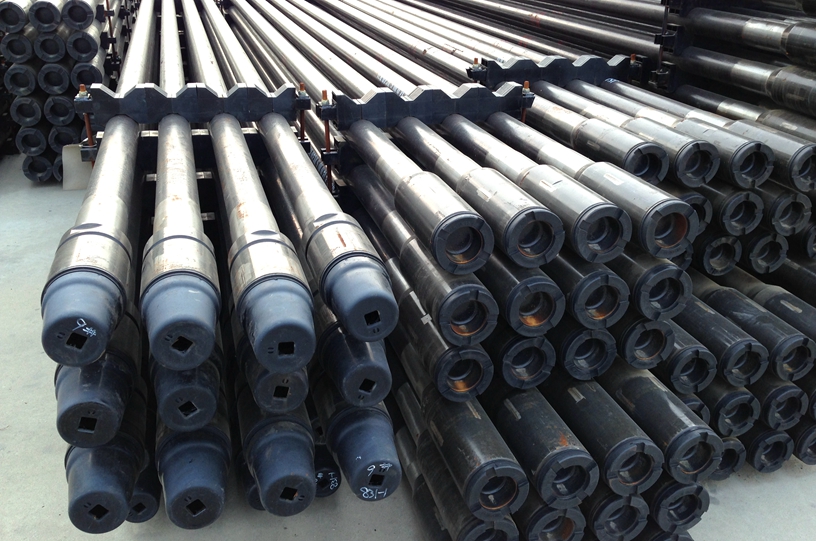

Drill Pipe

API 5DP

Material Requirements:

API 5DP specifies the material requirements for drill pipes. The material is typically alloy steel that meets specific chemical composition, mechanical properties, and heat treatment criteria to ensure strength, toughness, and resistance to the harsh conditions encountered in drilling operations.

Dimensions and Tolerances:

The specification provides detailed requirements for the dimensions and tolerances of drill pipes. This includes specifications for outside diameter, wall thickness, upset dimensions, and other critical dimensions. Tight tolerances are essential for maintaining the integrity and performance of the drill pipes.

Thread Connections:

API 5DP outlines standards for thread connections on drill pipes. This includes specifications for thread dimensions, taper, and pitch. The threaded connections must be designed to withstand high torque, axial loads, and dynamic forces encountered during drilling operations. API threading classifications, such as API Regular, API Internal Flush (IF), and API Full Hole (FH), are commonly used.

Upsetting and Heat Treatment:

Drill pipes often undergo upsetting, a process that increases the wall thickness at the ends to provide additional strength. API 5DP specifies the dimensions and requirements for upsetting. Heat treatment processes are also outlined to achieve the desired material properties.

Inspection and Testing:

The specification includes provisions for inspection and testing of drill pipes. This involves visual inspection, dimensional checks, and various non-destructive testing methods, such as ultrasonic and electromagnetic inspection, to ensure the integrity of the pipes.

Identification and Marking:

Each drill pipe is required to be clearly marked with information such as the manufacturer's name or trademark, size, weight, grade, and other relevant details. This marking helps in traceability and identification of the pipe's specifications.

Quality Control:

Manufacturers are required to implement quality control measures throughout the manufacturing process. This includes documentation of materials used, inspection results, and compliance with the specified requirements. Proper documentation is crucial for traceability and quality assurance.

API Monogram:

- Manufacturers that comply with API 5DP and pass the necessary audits have the option to apply for an API Monogram. The API Monogram is a mark of quality and compliance with API standards, providing additional assurance to end-users.

Protective Coatings:

- Drill pipes may be provided with protective coatings to enhance corrosion resistance and prevent damage during handling and transportation. These coatings must meet the specified requirements of API 5DP.

Handling and Storage:

API 5DP provides guidelines for the proper handling, storage, and transportation of drill pipes to prevent damage and ensure that the pipes maintain their integrity from the manufacturing facility to the drilling site.

Specifications - Tool Joints

| Tool joint designation | Size and style | Nom. Wt. Ib/ft | Grade | Outside Dia. of Pin and Box D | of Pin and Box D Inside Dia. of Pin d | Bevel Dia. of Pin and Box shoulder DF | Total length Tool Joint Pin LP | Pin Tong Space LPB | Box Tong Space LB | Combined Length of pin And Box L | Dia. of Box at Elevator Upset DPE | Dia. of Box at Elevator Upset DTE | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NC26 2 3/8IF 2 9/16 | 23/8EU | 6.65 | E | 3 3/8 | 1 3/4 | 3 17/64 | 10.00 | 7 | 8 | 15 | 2 9/16 | 2 9/16 | |

| X | 3/3 8 | 1/3 4 | 3 17/64 | 10.00 | 7 | 8 | 15 | 2 9/16 | 2 9/16 | ||||

| G | 3 3/8 | v | 3 17/64 | 10.00 | 7 | 8 | 15 | 2 9/16 | 2 9/16 | ||||

| NC31 2 7/8IF | 2 7/8EU | 10.40 | E | 4 1/8 | 2 1/8 | 3 61/64 | 10 1/2 | 7 | 9 | 16 | 3 3/16 | 3 3/16 | |

| X | 4 1/8 | 2 | 3 61/64 | 10 1/2 | 7 | 9 | 16 | 3 3/16 | 3 3/16 | ||||

| G | 4 1/8 | 2 | 3 61/64 | 10 1/2 | 7 | 9 | 16 | 3 3/16 | 3 3/16 | ||||

| s | 4 3/8 | 1 5/8 | 3 61/64 | 10 1/2 | 7 | 9 | 16 | 3 3/16 | 3 3/16 | ||||

| NC38 | 3 1/2EU | 9.50 | E | 4 3/4 | 2 11/16 | 4 37/64 | 11 1/2 | 8 | 10 1/2 | 18 1/2 | 3 7/8 | 3 7/8 | |

| NC38 3 1/2IF | 3 1/2EU | 13.3 | E | 4 3/4 | 2 11/16 | 4 37/64 | 12 | 8 | 10 1/2 | 18 1/2 | 3 7/8 | 3 7/8 | |

| X | 5 | 2 9/16 | 4 37/64 | 12 | 8 | 10 1/2 | 18 1/2 | 3 7/8 | 3 7/8 | ||||

| G | 5 | 2 7/16 | 4 37/64 | 12 | 8 | 10 1/2 | 18 1/2 | 3 7/8 | 3 7/8 | ||||

| s | 5 | 2 1/8 | 4 37/64 | 12 | 8 | 10 1/2 | 18 1/2 | 3 7/8 | 3 7/8 | ||||

| 15.5 | E | 5 | 2 9/16 | 4 37/64 | 12 | 8 | 10 1/2 | 18 1/2 | 3 7/8 | 3 7/8 | |||

| X | 5 | 2 7/16 | 4 37/64 | 12 | 8 | 10 1/2 | 18 1/2 | 3 7/8 | 3 7/8 | ||||

| G | 5 | 2 1/8 | 4 37/64 | 12 | 8 | 10 1/2 | 18 1/2 | 3 7/8 | 3 7/8 | ||||

| NC40 4FH | 3 1/2EU | 15.5 | s | 5 1/2 | 2 1/4 | 5 1/64 | 11 1/2 | 7 | 10 | 17 | 3 7/8 | 3 7/8 | |

| 4IU | 14.0 | E | 5 1/4 | 2 13/16 | 5 1/64 | 11 1/2 | 7 | 10 | 17 | 4 3/16 | 4 3/16 | ||

| x | 5 1/4 | 2 11/16 | 5 1/64 | 11 1/2 | 7 | 10 | 17 | 4 3/16 | 4 3/16 | ||||

| G | 5 1/2 | 2 7/16 | 5 1/64 | 11 1/2 | 7 | 10 | 17 | 4 3/16 | 4 3/16 | ||||

| S | 5 1/2 | 2 | 5 1/64 | 11 1/2 | 7 | 10 | 17 | 4 3/16 | 4 3/16 | ||||

| NC46 4IF | |||||||||||||

| 4 EU | 14.00 | E | 6 | 3 1/4 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 1/2 | 4 1/2 | ||

| X | 6 | 3 1/4 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 1/2 | 4 1/2 | ||||

| G | 6 | 3 1/4 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 1/2 | 4 1/2 | ||||

| S | 6 | 3 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 1/2 | 4 1/2 | 4 1/2IU | 13.75 | E | 6 | 3 3/8 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 11/16 | 4 11/16 |

| 16.6 | E | 6 1/4 | 3 1/4 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 11/16 | 4 11/16 | |||

| X | 6 1/4 | 3 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 11/16 | 4 11/16 | ||||

| G | 6 1/4 | 3 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 11/16 | 4 11/16 | ||||

| S | 6 1/4 | 2 3/4 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 11/16 | 4 11/16 | ||||

| 4 1/2IEU | 20.00 | E | 6 1/4 | 3 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 11/16 | 4 11/16 | ||

| X | 6 1/4 | 2 3/4 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 11/16 | 4 11/16 | ||||

| G | 6 1/4 | 2 1/2 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 11/16 | 4 11/16 | ||||

| S | 6 1/4 | 2 1/4 | 5 23/32 | 11 1/2 | 7 | 10 | 17 | 4 11/16 | 4 11/16 | ||||

Specifications - Drill Pipe

| Size | weight Designation |

Plain-end weight (Wpe) | outside diameter (D) | Well Thickness (T) | Grade | upset Ends for weld-on tool joints | |||

| lb/ft | kg/m | in | mm | ||||||

| 2 3/8 | 6.65 | 6.27 | 9.33 | 2.375 | 60.3 | 0.28 | 7.11 | E , X , G ,S | Ext. Upset |

| 2 7/8 | 10.4 | 9.72 | 14.47 | 2.875 | 73 | 0.362 | 9.19 | E , X , G ,S | Int. Upset or Ext. Upset |

| 3 1/2 | 9.5 | 8.81 | 13.12 | 3.5 | 88.9 | 0.254 | 6.45 | E | Int. Upset or Ext. Upset |

| 3 1/2 | 13.3 | 12.32 | 18.34 | 3.5 | 88.9 | 0.368 | 9.35 | E ,X,G,S | Int. Upset or Ext. Upset |

| 3 1/2 | 15.5 | 14.64 | 21.79 | 3.5 | 88.9 | 0.449 | 11.4 | E | Int. Upset or Ext. Upset |

| 3 1/2 | 15.5 | 14.64 | 21.79 | 3.5 | 88.9 | 0.449 | 11.4 | X ,G ,S | Int. Upset or Ext. Upset |

| 4 | 14 | 12.95 | 19.27 | 4 | 101.6 | 0.33 | 8.38 | E,X,G,S | Int. Upset or Ext. Upset |

| 4 1/2 | 13.75 | 12.25 | 18.23 | 4.5 | 114.3 | 0.271 | 6.88 | E | Int. Upset or Ext. Upset |

| 4 1/2 | 16.6 | 15 | 22.32 | 4.5 | 114.3 | 0.43 | 10.92 | E.X,G,S | Ext. Upset or Int. Upset |

| 4 1/2 | 20 | 18.71 | 27.84 | 4.5 | 114.3 | 0.43 | 10.92 | E,X,G,S | Ext. Upset or Int. Upset |

| 5 | 15.25 | 14.88 | 22.16 | 5 | 127 | 0.295 | 7.52 | X,G,S | Int. Upset |

| 5 | 19.5 | 17.95 | 26.5 | 5 | 127 | 0.362 | 9.19 | E | Int-Ext Upset |

| 5 | 19.5 | 17.95 | 26.5 | 5 | 127 | 0.362 | 9.19 | X,G,S | Ext. Upset or int-ext upset |

| 5 | 25.6 | 24.05 | 35.8 | 5 | 127 | 0.5 | 12.7 | E | Int-Ext Upset |

| 5 | 25.6 | 24.05 | 35.8 | 5 | 127 | 0.5 | 12.7 | X,G,S | Ext. Upset or Int-Ext Upset |

| 5 1/2 | 21.9 | 19.83 | 29.52 | 5.5 | 139.7 | 0.361 | 9.17 | E,X,G,S | Int-Ext Upset |

| 5 1/2 | 24.7 | 22.55 | 33.57 | 5.5 | 139.7 | 0.415 | 10.54 | E,X,G,S | Int-Ext Upset |

| 6 5/8 | 25.2 | 22.21 | 33.04 | 5.625 | 168.3 | 0.33 | 8.38 | E,X,G,S | Int-Ext Upset |

| 6 5/8 | 27.72 | 24.24 | 36.06 | 5.625 | 168.3 | 0.362 | 9.19 | E,X,G,S | Int-Ext Upset |

Important Note:

Information given in this data sheet about the condition or usability of materials respectively products are no warranty for their properties, but act as a description. The information we give on for advice, comply to the experiences of the manufacturer as well as our own. We cannot give a warranty for the results of processing and application of the products.